General Introduction’╝Ü

Application and Performance’╝Ü

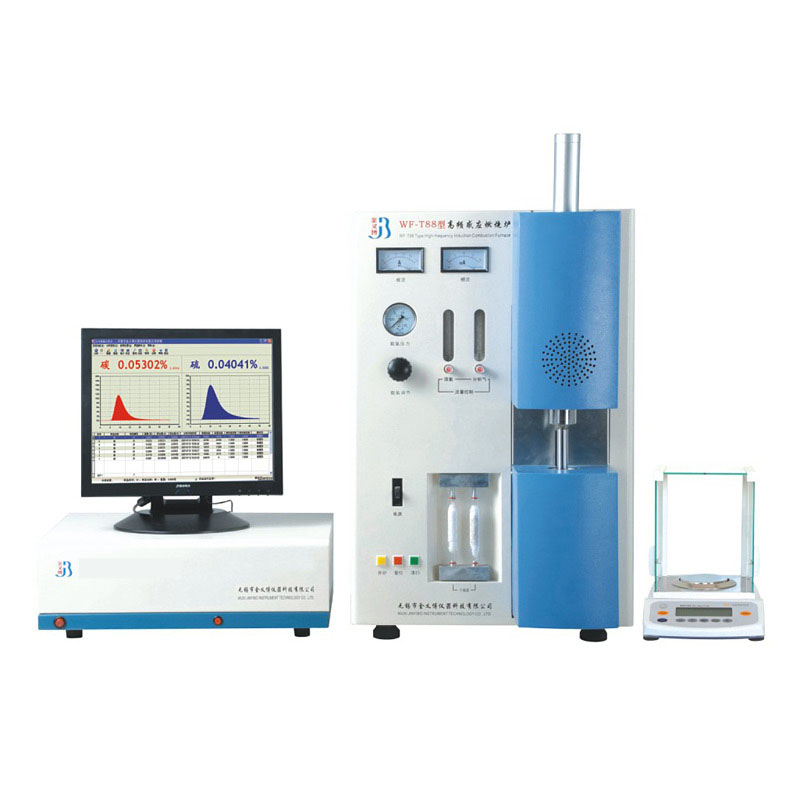

8820 Infrared Carbon & Sulfur Analyzer, being used coordinately with WF-L88 High-Frequency Induction Combustion Furnace, can determine the quality fraction of carbon and sulfur contained in steel, iron, alloy, non-ferrous metal, cement, ore, activator, glass, ceramic and other materials rapidly and accurately. This set of equipment is the high-tech product integrating optical, mechanical, electronic, computerization and analytical technologies. It characterizes itself in having wide range of measurement, precise and reliable results of analysis and the like advantages. Due to application of computerized technology, it has so far reached the advanced level domestically in respect to intellectualization of the instrument, the screen display of images and graphs, and collection and processing of data. It can be regarded as an ideal analyzer for various sectors to determine carbon and sulfur contents.

Component and Structure’╝Ü

This instrument consists of infrared testing unit, high-frequency induction heating unit, computer, printer and electronic balance. See fig. (1) The following text will mainly describe the internal structure of high-frequency induction heating unit and infrared testing unit.

The high-frequency induction heating unit in frame structure has three layers. (Upper, middle and low layer) In the upper layer there are the high frequency inducting circuit, the over-current and over-time protection circuit and the electromagnetic valve control circuit; in the middle layer there are power source, the gas path breaking switch, the components for filtration and drying of the analytical gases; in the lower layer there are the HV transformer, the dust collector, and compress valve etc. From the front view, the left upper section includes plate current indication ammeter, grid current indication ammeter, supporting oxygen pressure gauge and adjusting knob, top oxygen flow regulator and analytical gas flow regulator. The lower part includes the furnace uplift & descent switch, over-current & over-time reset button, automatic cleaning button, power switch and the dryer. The right section is the combustion area for the furnace of which the upper part is mounted with the filtration and cleaning systems for the gases released after combustion while the lower part bearing the cylinder which is used for transmitting the testing sample into the combustion area during the sample analysis and taking the testing sample out of the combustion area at the end of combustion.

The infrared testing unit has two layers. In the upper layer there are modular power and Control PCB. In the lower layer, there is the gas analysis room, which consists of a carbon analysis tank, sulfur-analysis tank and current stabilizer.

Technical index’╝Ü

Range of Measurement:

Accuracy and Precision:

Accuracy: Carbon confirms to the Standards ISO9556

Sulfur confirms to the Standards ISO4935

Precision: confirms National Metrological Verification Standards JJG395-97

Time of Analysis: Adjustable at 25~60 seconds, but generally at about 35 seconds

Min. reading: 0.00001%

Min. reading: Weighing range: 0~120 g, Precision of readers: 0.0001 g