ŌŚŗ Siemens PLC adopted as the core control system which makes sure the system is more reliable; No human interference required during the whole testing process, test temperature, shrink grading X, thickness Y of pectin layer are all tested and controlled automatically, real-time equipment status will be displayed on the PC.

ŌŚŗ With robot manipulator, it imitates human hands, it can accurately test lean coal and meager lean coal with Y value < 7.

ŌŚŗ Furnace blocks can be changed quickly, automatically identify the termination of the test, thus to improve the test efficiency.

ŌŚŗ Coal cups are laid side by side while the lever pressed vertically, itŌĆÖs more convenient to load coal sample thus solved the problem of graphic distortion and test result not accurate caused by cup blocking.

ŌŚŗ Counter weights loaded mechanically, lower labor intensity.

ŌŚŗ Temperature and volume data are all saved automatically for each test, re-check available, test data and curves recoverable and test report printable.

ŌŚŗ Function with extra low temperature failure, extra high temperature failure and thermocouple failure protection.

ŌŚŗ With temperature and shift correction fuction.

ŌŚŗ Optional auto-cup cleaner available which can clean coal cups absolutely and be more convenient for operators.

Application:

Sundy SDPI200 Dual Furnaces Full-automatic Bituminous Coal Plastometric Indices Tester is to determine the pectin layer index of bituminous coal (Maximum thickness Y of Pectin layer, maximum shrink grading X, curve shape and other parameters’╝ē, describe technical characteristics of coke and give information of coking and coal blending. ItŌĆÖs widely used to departments of coal, metallurgy, chemistry and inspection laboratories.

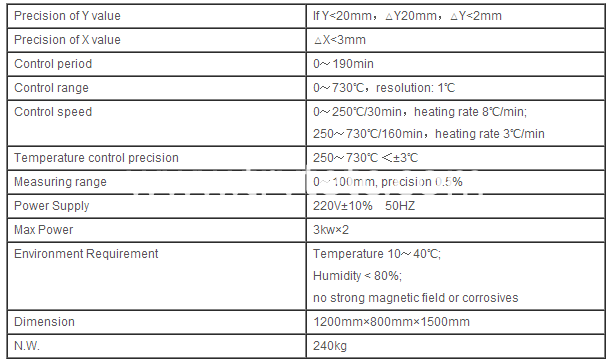

Specifications: